Funnel magnets

Funnel magnets

The permanent use of magnetic funnels is recommendable for filtering

ferritic impurities in plastics processing, on injection moulding machines,

extruders and for specific processing methods for granulate, ground material,

powder or fluids.

Ferritic impurities such as nails, screws, clips, pieces of wire and iron

swarf can be found in many inorganic and plant-based crude products.

These impurities can lead to machine failure and impair product quality.

Funnel magnets prevent damage in a rotating screw, cylinder and nozzle.

They ensure trouble-free operation prevent additional costs. Tips

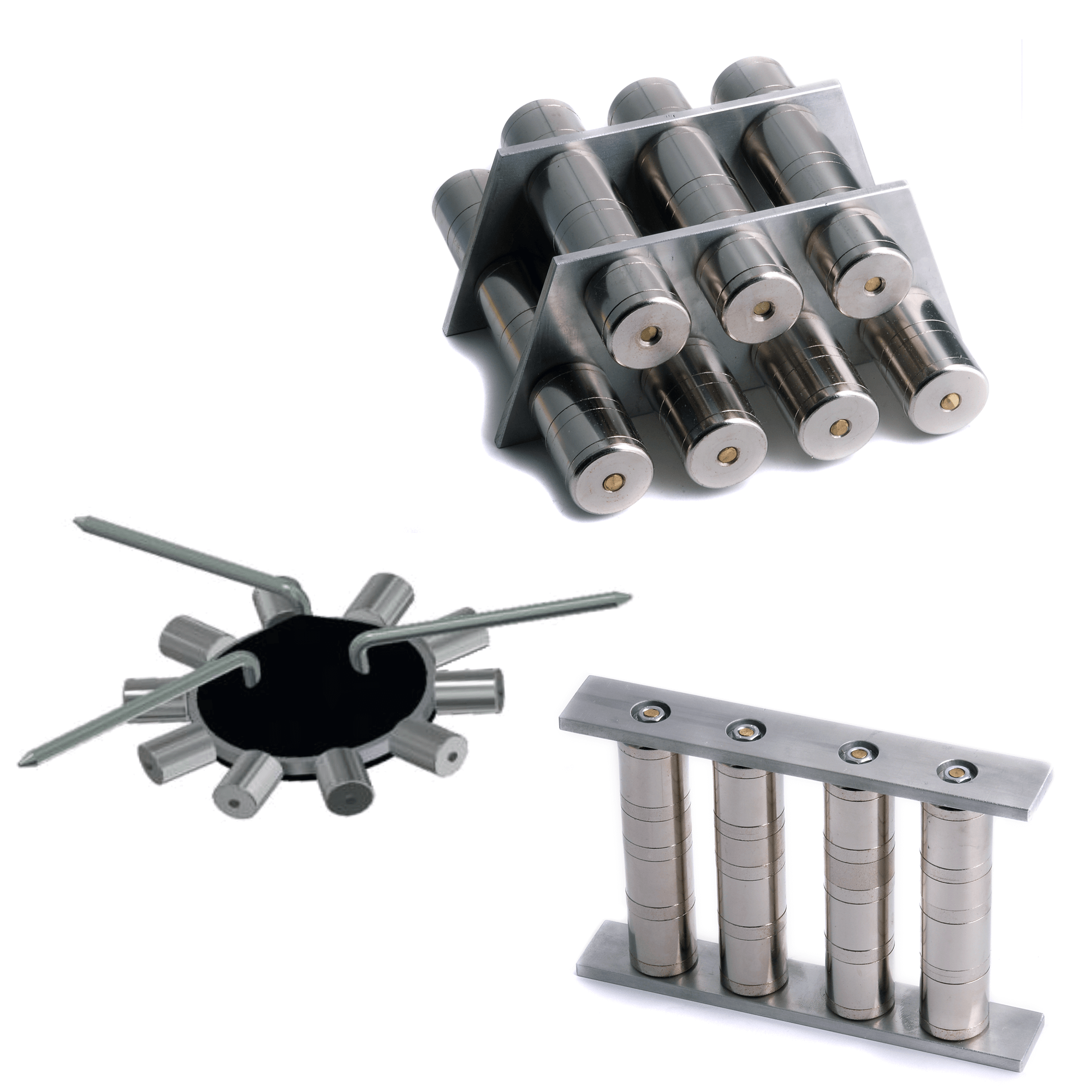

Type R, single-row for round funnels

Ferritic impurities in the granulate is captured by the magnets without affecting the flow. The spacers can be finished in aluminium or 18/10 nickel

chromium steel depending on your requirements. Type E/D, double-row for angular funnels

Type R/D, double-row for round funnels

The E/D and R/D versions are best suited to situations demanding stringent

requirements. Due to the magnetic elements being positioned one

below the other, every particle touches a magnetic element directly once

when the fluid flows through the filter. Ferrous substances are captured

by the magnetic fields optimally and retained.

The spacing between the individual magnetic bars can be modified according

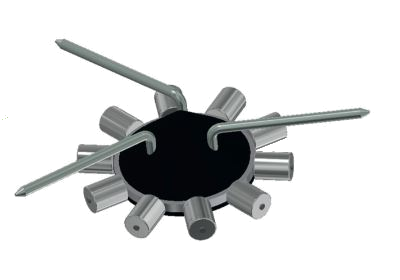

to the free-flowing properties and particle size of the fluid being filtered. Type RS for round funnels

A very strong homogeneous magnetic field with a high flux density is

created thanks to the share of magnets in the RS version. This version is

particularly suited to small outlet orifices.

The spacing required the funnel wall and the magnet are adjusted using

the three infinitely adjustable support arms.

Download the request-chart here E, E/D, R, R/D, RS ser ies

The permanent use of magnetic funnels is recommendable for filtering

ferritic impurities in plastics processing, on injection moulding machines,

extruders and for specific processing methods for granulate, ground material,

powder or fluids.

Ferritic impurities such as nails, screws, clips, pieces of wire and iron

swarf can be found in many inorganic and plant-based crude products.

These impurities can lead to machine failure and impair product quality.

Funnel magnets prevent damage in a rotating screw, cylinder and nozzle.

They ensure trouble-free operation prevent additional costs. Tips

- A stainless steel version is also available for the food industry.

- All funnel magnets with the exception of the TYPE RS are produced to client specification.

Type R, single-row for round funnels

Ferritic impurities in the granulate is captured by the magnets without affecting the flow. The spacers can be finished in aluminium or 18/10 nickel

chromium steel depending on your requirements. Type E/D, double-row for angular funnels

Type R/D, double-row for round funnels

The E/D and R/D versions are best suited to situations demanding stringent

requirements. Due to the magnetic elements being positioned one

below the other, every particle touches a magnetic element directly once

when the fluid flows through the filter. Ferrous substances are captured

by the magnetic fields optimally and retained.

The spacing between the individual magnetic bars can be modified according

to the free-flowing properties and particle size of the fluid being filtered. Type RS for round funnels

A very strong homogeneous magnetic field with a high flux density is

created thanks to the share of magnets in the RS version. This version is

particularly suited to small outlet orifices.

The spacing required the funnel wall and the magnet are adjusted using

the three infinitely adjustable support arms.

Download the request-chart here E, E/D, R, R/D, RS ser ies